We are always on hand if you have any problems and we welcome queries by telephone or email. We pride ourselves on our exceptional customer support to ensure your metal thickness meter is always working to its best performance. Below are some options that may help you in the first instance, otherwise please feel free to contact us, no matter how small your question.We appreciate the opportunity to speak to our customers – one call can make all the difference.

FAQ’s

What type of coatings can multiple echo ignore?

Metal thickness meters using Multiple echo can ignore most types of coatings as long as they are solidly adhered to the surface. Any de-laminations will affect measurements, but then the coating is no longer serviceable and will have to be removed and replaced anyway. Coatings containing ‘particles’ may cause problems because the ultrasound is deflected.

How thick can the coatings be?

Typically the coating can be up to 6 mm thick but we have the option to select a mode called Coating Plus+ for measuring through thicker coatings up to 20 mm thick, depending on the coating type.

Will the multiple echo measure on corroded surfaces?

Yes, mulitple echo works very well on corroded surfaces. Pits on the front face can be filled with couplant and the probe used to straddle the pit. This will give the metal thickness from the bottom of the pit to the back wall. The couplant will be ignored as if it were a coating. This also means that a larger diameter probe can be used which gives better performance on returned ultrasound which has been scattered due to severe back wall corrosion.

Are there any alternatives to the issued couplant that I can use?

Although we recommend couplant specifically designed for taking measurements, other liquids can be used such as liquid soap, wallpaper paste, water and some hand cleansers. Grease is not a good alternative.

Can Tritex metal thickness meters measure all types of metal?

Yes, Tritex metal thickness meters can be calibrated to measure all types of metal which have a velocity range between 1000 m/s to 8000 m/s (0.0394 in/µs to 0.3150 in/µs).

Do Tritex multigauges need to be zeroed before each use?

No, the multiple echo technique employed by Tritex multigauges automatically zeros the probe with every measurement.

What is the purpose of the membrane on the probe face?

The membrane has two purposes; the main reason is to protect the probe face from damage, but we can also supply Teflon™ membranes that protect the probe from heat damage when measuring on hot surfaces.

Can different probes be used with different gauges?

Yes, all metal thickness meters in the range can be used with the full range of probes. However, probes for surface gauges are not compatible with probes for underwater gauges. All gauges have Intelligent Probe Recognition to ensure the correct probe is selected.

Can rechargeable batteries be used instead of disposables?

Yes, ‘AA’ disposable alkaline batteries can be replaced with rechargeable NiMH ‘AA’ batteries.

The display is showing three ascending lines and no measurement, why is this?

Tritex multigauges automatically verify each measurement by comparing echoes and checking they are equal. If they are not then three ascending lines are displayed. This indicates that echoes are being received back but the measurement is not verified. Therefore no spurious or confusing readings are displayed.

What warranty is supplied with all Tritex Gauges?

All Tritex metal thickness meters are supplied with a three year manufacturer’s warranty.

What standards are Tritex Multigauges manufactured to?

All metal thickness meters are manufactured to, and comply with, the new standard of manufacturing Ultrasonic Thickness Gauges – BS EN 15317:2013. This standard covers the characterisation and verification of ultrasonic thickness measuring equipment to ensure they meet certain criteria of performance and build quality.

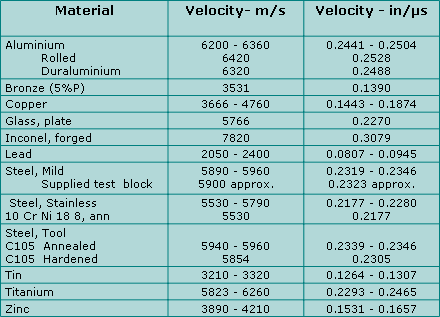

Ultrasonic Velocity Table

The given values are in certain cases strongly dependent on the alloy, heat treatment, manufacturing and processing and are therefore only approximate standard values. They are given here as a guide only.

Reference: Mathies, Klaus (1998), Thickness measurement with Ultrasound, Berlin: German Society of nondestructive testing.